Soluzione da 10 MW per centrali elettriche chiavi in mano

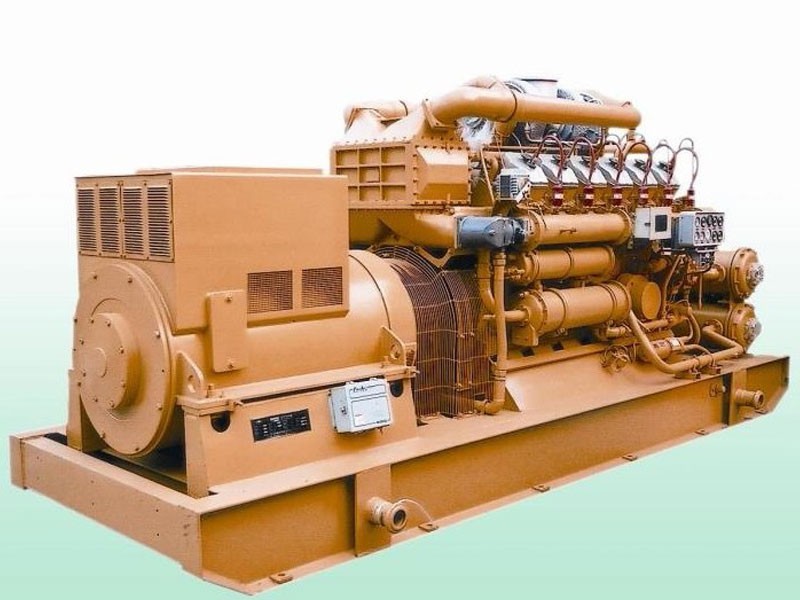

- CNPC JCPC

- Cina

1. Pacchetto soluzione per il cliente. potremmo fornire varie attrezzature per soddisfare la vostra richiesta.

2. Buon fornitore cinese di motori a gas, ha prodotto gruppi elettrogeni a gas da oltre 30 anni.

3. Due anni di garanzia, guida all'installazione gratuita, formazione del personale, ecc.

4. Tecnologia di controllo Woodward, sistema di accensione digitale Motortech e turbocompressore ABB.

Supply scope

Item | Qty. | Description | Sinogas | Owner |

1 | Design for 10MW power plant | |||

Holistic design for 10MW power plant | ■ | |||

2 | Basic supply scope of gas genset 1200GF9-T | |||

2.1 | Engine | |||

1/Set | H16V190ZLT-1 | ■ | ||

2.2 | Three-phase internal pole sync. Alternator | |||

1/Set | JFG series, 6600V, 60Hz | ■ | ||

2.3 | Genset components | |||

1/Set | Common base frame for 1200GF9-T | ■ | ||

1/Set | Flexible coupling for 1200GF9-T | ■ | ||

1/Set | Standard genset components for 1200GF9-T | ■ | ||

2.4 | Genset assembly | |||

1/Set | Genset assembly for 1200GF9-T | ■ | ||

2.5 | Control system | |||

1/Set | Genset control panel | ■ | ||

1/Set | Control system for 1200GF9-T genset | ■ | ||

1/Set | IG-NT Synchronization module | ■ | ||

1/Set | IC500 ignition system | ■ | ||

2.6 | Fuel gas supply System | |||

1/Set | Gas filter | ■ | ||

1/Set | Gas pressure regulator | ■ | ||

1/Set | Electromagnetic valve | ■ | ||

1/Set | Safety exhaust valve | ■ | ||

1/Set | Gas control valve | ■ | ||

1/Set | Mixer | ■ | ||

2.7 | Starter system | |||

2/Set | Electrical starting motor DC24V | ■ | ||

4/Set | Accumulator 195Ah | ■ | ||

1/Set | Battery charger AC22V/DC24V | ■ | ||

2.8 | LT cooling system | |||

1/set | Radiator(same with HT) | ■ | ||

10/set | Fan(same with HT) | ■ | ||

10/set | Motor(same with HT) | ■ | ||

1/Set | Engine cooling water pump | ■ | ||

1/Set | Temperature sensor | ■ | ||

1/Set | Aftercooler | ■ | ||

1/Set | Lubricating oil heat exchanger | ■ | ||

2.9 | HT cooling system | |||

1/set | Radiator(same with LT) | ■ | ||

10/set | Fan(same with LT) | ■ | ||

10/set | Motor(same with LT) | ■ | ||

1/Set | Engine cooling water pump | ■ | ||

1/Set | Temperature sensor | ■ | ||

2.10 | Intake air and Exhaust system | |||

2/Set | Air filter | ■ | ||

1/Set | Exhaust gas silencer | ■ | ||

1/Set | Set of flanges, gaskets, screws for exhaust silencer | ■ | ||

1/Set | Exhaust pipe | ■ | ||

1/Set | Silencer bracket | ■ | ||

1/Set | Silencer support | ■ | ||

1/Set | Heat insulation of exhaust pipe | ■ | ||

2.11 | Lubricating oil system | |||

1/Set | Luboil pump | ■ | ||

1/Set | Oil filter | ■ | ||

1/Set | Oil filter bypass-check valve | ■ | ||

1/Set | Centrifugal filter | ■ | ||

1/Set | Electric oil pre-feeding pump | ■ | ||

1/Set | Pressure limiting valve | ■ | ||

1/Set | Luboil sump | ■ | ||

1/Set | Oil pressure sensor | ■ | ||

1/set | Oil temperature sensor | ■ | ||

1/plant | Oil filling pump | ■ | ||

2.12 | Standard special spare parts | |||

1/Set | For engine: H16V190ZLT-2 | ■ | ||

2.13 | Standard documentation | |||

1/Set | Set of technical documentation | ■ | ||

2.14 | Tools | |||

2/Plant | Standard tools for maintenance | ■ | ||

1/Set | Standard special tools | ■ | ||

3 | Electrical equipment | |||

10/Plant | HV cabinet of genset | ■ | ||

1/Plant | PT cabinet(6.6kV) | ■ | ■ | |

1/Plant | DC cabinet | ■ | ■ | |

1/plant | Outlet cabinet of power plant | ■ | ■ | |

1/Plant | Incoming cabinet of transformer(for plant) | ■ | ■ | |

1/Plant | Transformer for power plant self-use(for plant) | ■ | ■ | |

1/Plant | Outlet cabinet of transformer(for pant) | ■ | ■ | |

3/Plant | LV Distribution cabinet in power plant | ■ | ■ | |

1/Plant | Cable | ■ | ■ | |

4 | Gas station for power plant | |||

1/Plant | Gas station for power plant | ■ | ||

5 | Erection work | |||

5.1 | Civil & architecture work | |||

1/Plant | Soil investigation report | ■ | ||

1/Plant | Site environment report | ■ | ||

1/Plant | Site land | ■ | ||

1/Plant | Site land leveling & cleaning | ■ | ||

1/Plant | Civil works, Foundations | ■ | ||

1/Plant | Road & paving for power plant | ■ | ||

1/Plant | Electric grounding | ■ | ||

1/Plant | Gas detection, firefighting system | ■ | ||

1/Plant | water supply system | ■ | ||

5.2 | Installation work | |||

1/Plant | Genset installation | ■ | ||

1/Plant | Installation for mechanical equipment | ■ | ||

1/Plant | Installation for electrical equipment | ■ | ||

1/Plant | Installation for piping/support | ■ | ||

1/Plant | Installation for AC & ventilation for electrical room, else | ■ | ||

1/Plant | Installation material and tools: piping, valve, insulation, steel, welding machine, crane, others. | ■ | ||

6 | Services | |||

6.1 | Packing | |||

1/Set | Packing | ■ | ||

6.2 | Transport | |||

1/Set | Transport to Chinese port | ■ | ||

1/Set | Transport to the site of power plant from Chinese port | ■ | ||

6.3 | Factory test | |||

1/Set | Engine test in factory | ■ | ||

6.4 | Supervision Installation | |||

1/Set | Installation supervision | ■ | ■ | |

6.5 | Commissioning | |||

1/Set | Commissioning | ■ | ■ | |

1/Set | 1st maintenance after commissioning | ■ | ■ | |

1/Set | Mineral oil for initial filling (L) | ■ | ||

1/Set | Initial filling water with antifreezes (L) | ■ | ||

6.6 | Training | |||

1/Plant | Operator training (per participant/one week) | ■ | ■ | |

7 | Other | |||

7.1 | 1/Plant | Custom clearance in the country of destination | ■ | |

7.2 | 1/Plant | Taxes & duties in the country of destination | ■ | |

7.3 | 1/Plant | Storage area for equipments in the country of destination | ■ | |

7.4 | 1/Plant | All applicable permits or approvals by government for pant | ■ | |

7.5 | 1/Plant | Accommodations for all engineers and workers in site | ■ | |

7.6 | 1/Plant | Insurance | ■ | |

7.7 | 1/Plant | other | ■ |